Manufacturing – To simply manage international competitive pressures, manufacturers must adopt highly integrated supply chains, smarter and smarter devices and multiple interconnected systems. However, many traditional manufacturing systems do not readily integrate multiple disparate systems or enable end to end operations visibility and optimization. According to CignitiTechnologies manufacturing will be the most impacted industry by the IoT transformation with and economic benefit of close to $3.9 trillion due to use and implementation of the IIoT. The benefits of IoT for manufacturing will come not only from end to end connectivity and analytics but also from the interconnecting of IoT systems. Manufacturing has always required EMS systems, but to realize the next wave of IoT productivity will require new levels of interworking not only from the sensor to back end analytics but ACROSS disparate back end systems for overall operations visibility, and this will be a challenge. However, crossing this chasm will yield many benefits:

Manufacturing – To simply manage international competitive pressures, manufacturers must adopt highly integrated supply chains, smarter and smarter devices and multiple interconnected systems. However, many traditional manufacturing systems do not readily integrate multiple disparate systems or enable end to end operations visibility and optimization. According to CignitiTechnologies manufacturing will be the most impacted industry by the IoT transformation with and economic benefit of close to $3.9 trillion due to use and implementation of the IIoT. The benefits of IoT for manufacturing will come not only from end to end connectivity and analytics but also from the interconnecting of IoT systems. Manufacturing has always required EMS systems, but to realize the next wave of IoT productivity will require new levels of interworking not only from the sensor to back end analytics but ACROSS disparate back end systems for overall operations visibility, and this will be a challenge. However, crossing this chasm will yield many benefits:

- 360 degree view into operations with deep visibility into interrelated cause and effect events. Root cause discovery and event correlations will be simpler, and operation performance will improve.

- Deeper cross functional visibility into operational efficiency will enable unified KPIs that matter most to business performance. Integrated systems will enable reduction of bottlenecks and minimization of unnecessary costs.

- Integration of supply chains further enable lean manufacturing methods and efficiency.

- Supplier quality can be more easily managed with and integrated and smart supply chain.

- Smart manufacturing lines as well as smart devices in the manufacturing process will provide diagnostic data, enable constant improvement and detect product defects at the source.

- Real time asset tracking and utilization will become integrated into the manufacturing process.

- Predictive analytics based on historical information and line-embedded and product embedded sensors allow the opportunity to take actions before significant problems occur.

- Integration of end to end supply chain will allow minimization of out of stock items in the manufacturing queue as well as optimize the match of product to customer demand.

However, many suggest that the addition of IoT to Manufacturing will be much more dramatic that the above list of “incremental” benefits, and that we are on the edge of a major shift in productivity, now dubbed as Industry 4.o. By integrating advanced IoT capabilities into manufacturing lines, service capabilities, dramatic improvements in cost and profit are expected, on the range of 18% and 5% respectively. One dramatic example of Industry 4.0 technology is the integration of “things” with “data” through augmented reality. In it’s recent LiveWorx’16, PTC demonstrated using a handheld device that could scan a Caterpillar generator, link to its real-time sensor data, diagnose likely problems, and then overlay on the CAT image step by step instructions for repair. This is the kind of dramatic productivity that will be possible with IIoT in manufacturing and with Industry 4.0.

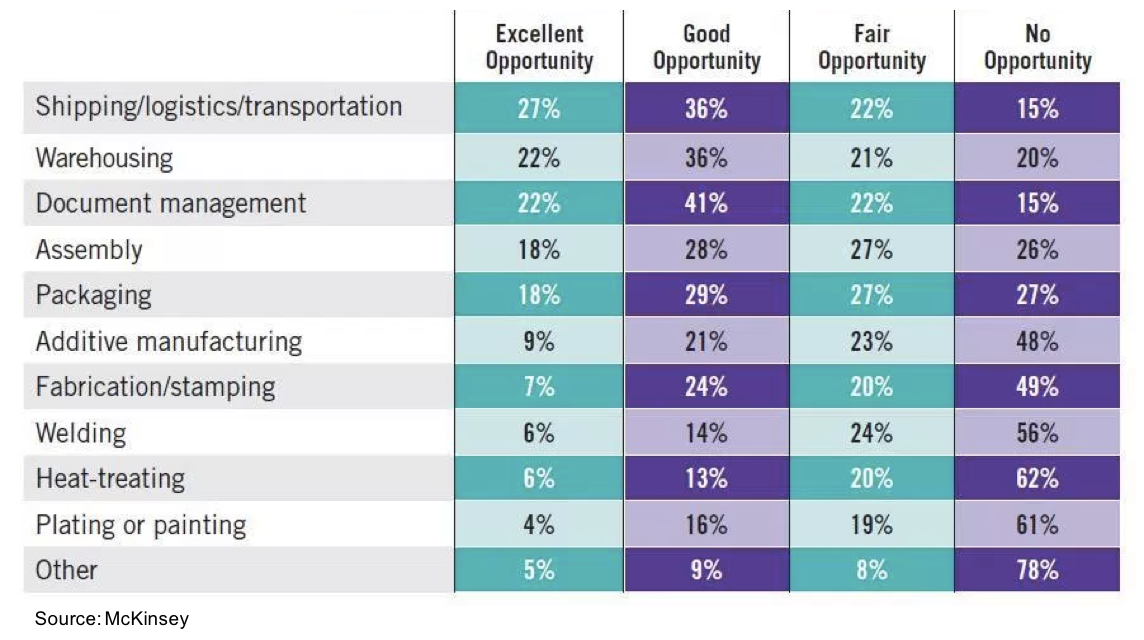

The chart below from McKinsey Highlights the processes that will benefit most from IoT integration: